- Home

- >

- OMP Adapters

- >

- Oil Metering Pump Adapters

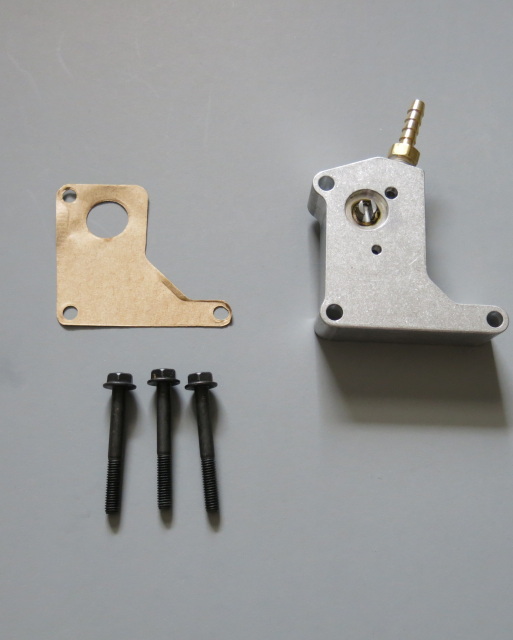

Oil Metering Pump Adapters

SKU:

$153.00

$153.00

Unavailable

per item

Rotary engines are designed to burn a small amount of oil in the engine to lubricate the apex seals. Our Oil Metering Pump Adapters are used in conjunction with the stock oil metering pump. allowing the driver to use clean burning 2 stroke oil in the combustion chamber, WITHOUT the inconvenience of pre-mixing oil in the fuel.

Only a few left!

Wankel engines, such as the one used in the MAZDA RX8 sports car, need oil in the combustion chamber to lubricating the apex seals.

Most stock rotary engines use a metering pump, which injects a small amount of engine oil from the oil pan into the intake manifold and/or directly into the combustion chamber. Engine oil is designed to lubricate sleeve bearings and carry heat from the engine interior.

When engine oil is injected into the combustion chamber, it only is partially burned, leaving some unburned deposits behind. These deposits can build up and reduce engine performance; cause the apex seals to stick; reduce compression and eventually lead to an engine overhaul.

One obvious method of preventing this is to disconnect the metering pump altogether, and mix two-stroke oil in the gasoline, as you would do with a lawn mower or older outboard engine. It has been demonstrated that two-stroke oil is an effective lubricant , burns clean and leaves behind almost no residue or deposits. However, the inconvenience of carrying 2 stroke oil, and a funnel in the car, make this option unattractive to many rotary drivers.

The Metering Pump Adapter, as offered by RotaryAviation.com, provides the solution to this problem. It allows the the builder to still use the stock metering pump, but supply it with two-stroke oil. With the OMP adapter installed, all that is needed is a small oil tank with two-stroke oil, connected to the OMP Adapter. The oil level in the tank should never be less than 6” above the metering pump.

Oil consumption is approximately 1/100 of fuel burned.

Most stock rotary engines use a metering pump, which injects a small amount of engine oil from the oil pan into the intake manifold and/or directly into the combustion chamber. Engine oil is designed to lubricate sleeve bearings and carry heat from the engine interior.

When engine oil is injected into the combustion chamber, it only is partially burned, leaving some unburned deposits behind. These deposits can build up and reduce engine performance; cause the apex seals to stick; reduce compression and eventually lead to an engine overhaul.

One obvious method of preventing this is to disconnect the metering pump altogether, and mix two-stroke oil in the gasoline, as you would do with a lawn mower or older outboard engine. It has been demonstrated that two-stroke oil is an effective lubricant , burns clean and leaves behind almost no residue or deposits. However, the inconvenience of carrying 2 stroke oil, and a funnel in the car, make this option unattractive to many rotary drivers.

The Metering Pump Adapter, as offered by RotaryAviation.com, provides the solution to this problem. It allows the the builder to still use the stock metering pump, but supply it with two-stroke oil. With the OMP adapter installed, all that is needed is a small oil tank with two-stroke oil, connected to the OMP Adapter. The oil level in the tank should never be less than 6” above the metering pump.

Oil consumption is approximately 1/100 of fuel burned.